Page 30 - Dual-line-automatic

P. 30

Metering device

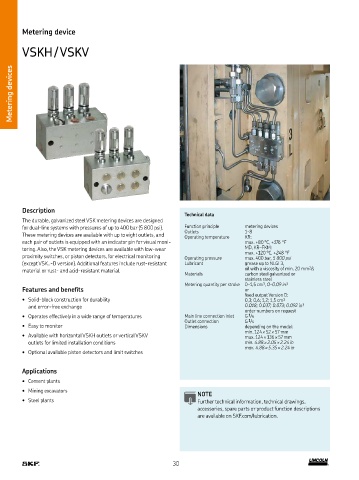

VSKH / VSKV

Metering devices

Description

Technical data

The durable, galvanized steel VSK metering devices are designed

for dual-line systems with pressures of up to 400 bar (5 800 psi) Function principle metering devices

These metering devices are available with up to eight outlets, and Outlets 1-8

Operating temperature KR:

each pair of outlets is equipped with an indicator pin for visual moni- max +80 °C, +176 °F

toring Also, the VSK metering devices are available with low-wear MD, KR–FKM:

max +120 °C, +248 °F

proximity switches, or piston detectors, for electrical monitoring Operating pressure max 400 bar, 5 800 psi

(except VSK -D version) Additional features include rust-resistant Lubricant grease up to NLGI 3,

material or rust- and acid-resistant material oil with a viscosity of min 20 mm 2 /s

Materials carbon steel galvanized or

stainless steel

Metering quantity per stroke 0–1,5 cm 3 , 0–0.09 in 3

Features and benefits or

fixed output Version D:

• Solid-block construction for durability 0,3; 0,6; 1,2; 1,5 cm 3

and error-free exchange 0.018; 0.037; 0.073; 0.092 in 3

order numbers on request

1

• Operates effectively in a wide range of temperatures Main line connection inlet G /4

1

Outlet connection G /4

• Easy to monitor Dimensions depending on the model:

min 124 × 52 × 57 mm

• Available with horizontal VSKH outlets or vertical VSKV max 124 × 136 × 57 mm

outlets for limited installation conditions min. 4.88 × 2.05 × 2.24 in

max. 4.88 × 5.35 × 2.24 in

• Optional available piston detectors and limit switches

Applications

• Cement plants

• Mining excavators

NOTE

• Steel plants Further technical information, technical drawings,

accessories, spare parts or product function descriptions

are available on SKF com/lubrication

30