Page 81 - Rollingbearings

P. 81

Selection criteria

Speed and friction • Bearings with rolling elements made of

ceramics (hybrid bearings) accommodate

The permissible operating temperature of higher speeds than their allsteel

rolling bearings imposes limits on the speed equivalents

at which they can be operated The operating

temperature is determined, to a great extent,

on the frictional heat generated in the bearing,

except in machines where process heat is

dominant

An overview is provided in Suitability of

rolling bearings for industrial applications,

page 72, of the speed capability of various

bearing types

When selecting bearing type on the basis

of operating speed, you should consider the

following:

• Ball bearings have a lower frictional

moment than samesized roller bearings

• Thrust bearings cannot accommodate

speeds as high as samesized radial

bearings

• Single row bearing types typically gener

ate low frictional heat and are therefore

Bearing type and arrangement

more suitable for high speed operation

than double or multirow bearings

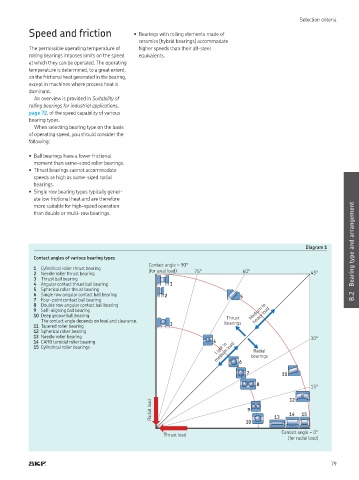

Diagram 1

Contact angles of various bearing types

Contact angle = 90°

1 Cylindrical roller thrust bearing (for axial load) 75° 60°

2 Needle roller thrust bearing 45°

3 Thrust ball bearing

4 Angular contact thrust ball bearing 1

5 Spherical roller thrust bearing

6 Single row angular contact ball bearing 2 5 B.2

7 Fourpoint contact ball bearing

8 Double row angular contact ball bearing

9 Selfaligning ball bearing Medium to

10 Deep groove ball bearing Thrust heavy load

The contact angle depends on load and clearance bearings

11 Tapered roller bearing 3

12 Spherical roller bearing

13 Needle roller bearing 30°

14 CARB toroidal roller bearing 4

medium load

15 Cylindrical roller bearings Light to bearings

Radial

6

7 11

8 15°

Radial load 9 12 15

14

10 13

Contact angle = 0°

Thrust load

(for radial load)

79