Page 107 - Rollingbearings

P. 107

Size selection based on static load

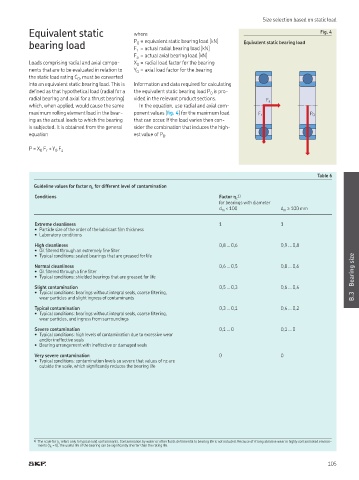

Equivalent static where Fig. 4

bearing load P = equivalent static bearing load [kN] Equivalent static bearing load

0

F = actual radial bearing load [kN]

r

F = actual axial bearing load [kN]

a

Loads comprising radial and axial compo- X = radial load factor for the bearing

0

nents that are to be evaluated in relation to Y = axial load factor for the bearing

0

the static load rating C , must be converted

0

into an equivalent static bearing load. This is Information and data required for calculating

deined as that hypothetical load (radial for a the equivalent static bearing load P is pro-

0

radial bearing and axial for a thrust bearing) vided in the relevant product sections. F a

which, when applied, would cause the same In the equation, use radial and axial com-

maximum rolling element load in the bear- ponent values (ig. 4) for the maximum load F r P 0

ing as the actual loads to which the bearing that can occur. If the load varies then con-

is subjected. It is obtained from the general sider the combination that induces the high-

equation est value of P .

0

P = X F + Y F

0 a

0 r

Table 6

for different level of contamination

Guideline values for factor η c

Conditions Factor η c 1)

for bearings with diameter

d < 100 d ≥ 100 mm

m

m

Extreme cleanliness 1 1

• Particle size of the order of the lubricant ilm thickness

• Laboratory conditions

High cleanliness 0,8 ... 0,6 0,9 ... 0,8

• Oil iltered through an extremely ine ilter

• Typical conditions: sealed bearings that are greased for life

Normal cleanliness 0,6 ... 0,5 0,8 ... 0,6

• Oil iltered through a ine ilter Bearing size

• Typical conditions: shielded bearings that are greased for life

Slight contamination 0,5 ... 0,3 0,6 ... 0,4

• Typical conditions: bearings without integral seals, coarse iltering,

wear particles and slight ingress of contaminants B.3

Typical contamination 0,3 ... 0,1 0,4 ... 0,2

• Typical conditions: bearings without integral seals, coarse iltering,

wear particles, and ingress from surroundings

Severe contamination 0,1 ... 0 0,1 ... 0

• Typical conditions: high levels of contamination due to excessive wear

and/or ineffective seals

• Bearing arrangement with ineffective or damaged seals

Very severe contamination 0 0

• Typical conditions: contamination levels so severe that values of ηc are

outside the scale, which signiicantly reduces the bearing life

1) The scale for η c refers only to typical solid contaminants. Contamination by water or other luids detrimental to bearing life is not included. Because of strong abrasive wear in highly contaminated environ-

ments (η c = 0), the useful life of the bearing can be signiicantly shorter than the rating life.

105