Page 25 - Single-line automatic lubrication systems

P. 25

Pump unit

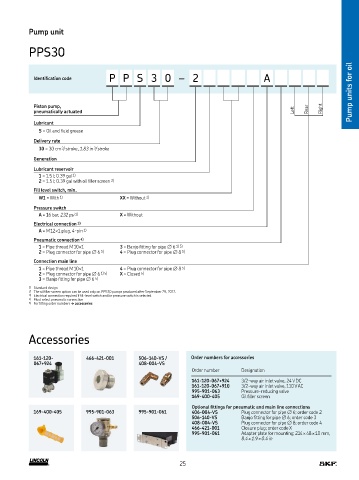

PPS30

Pump units for oil

P P S 3 0 – 2 A

Identification code

Piston pump, Right

pneumatically actuated Left Rear

Lubricant

S = Oil and fluid grease

Delivery rate

30 = 30 cm 3 / stroke, 1.83 in 3 / stroke

Generation

Lubricant reservoir

1 = 1.5 l; 0.39 gal 1)

2 = 1.5 l; 0.39 gal with oil filler screen 2)

Fill level switch, min

W1 = With 1) XX = Without 2)

Pressure switch

A = 16 bar, 232 psi 1) X = Without

Electrical connection 3)

A = M 12×1 plug, 4-pin 1)

Pneumatic connection 4)

1 = Pipe thread M 10×1 3 = Banjo fitting for pipe ∅ 6 1) 5)

2 = Plug connector for pipe ∅ 6 5) 4 = Plug connector for pipe ∅ 8 5)

Connection main line

1 = Pipe thread M 10×1 4 = Plug connector for pipe ∅ 8 5)

2 = Plug connector for pipe ∅ 6 1) 5) X = Closed 5)

3 = Banjo fitting for pipe ∅ 6 5)

1) Standard design

2) The oil filler screen option can be used only on PPS30 pumps produced after September 29, 2017.

3) Electrical connection required if fill-level switch and/or pressure switch is selected

4) Must select pneumatic connection

5) For fitting order numbers † accessories

Accessories

161-120- 466-421-001 506-140-VS / Order numbers for accessories

067+924 408-004-VS

Order number Designation

161-120-067+924 3/2-way air inlet valve, 24 V DC

161-120-067+910 3/2-way air inlet valve, 110 V AC

995-901-063 Pressure-reducing valve

169-400-405 Oil filler screen

Optional fittings for pneumatic and main line connections

169-400-405 995-901-063 995-901-061 406-004-VS Plug connector for pipe ∅ 6; order code 2

506-140-VS Banjo fitting for pipe ∅ 6; order code 3

408-004-VS Plug connector for pipe ∅ 8; order code 4

466-421-001 Closure plug; order code X

995-901-061 Adapter plate for mounting; 214 × 48 × 10 mm,

8.4 × 1.9 × 0.4 in

25