Page 28 - Y-bearing-units

P. 28

Selection of Y-bearing unit type

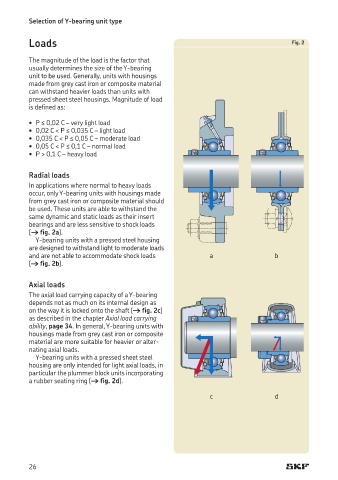

Loads Fig. 2

The magnitude of the load is the factor that

usually determines the size of the Y-bearing

unit to be used. Generally, units with housings

made from grey cast iron or composite material

can withstand heavier loads than units with

pressed sheet steel housings. Magnitude of load

is defined as:

• P ≤ 0,02 C – very light load

• 0,02 C < P ≤ 0,035 C – light load

• 0,035 C < P ≤ 0,05 C – moderate load

• 0,05 C < P ≤ 0,1 C – normal load

• P > 0,1 C – heavy load

Radial loads

In applications where normal to heavy loads

occur, only Y-bearing units with housings made

from grey cast iron or composite material should

be used. These units are able to withstand the

same dynamic and static loads as their insert

bearings and are less sensitive to shock loads

(† fig. 2a).

Y-bearing units with a pressed steel housing

are designed to withstand light to moderate loads

and are not able to accommodate shock loads a b

(† fig. 2b).

Axial loads

The axial load carrying capacity of a Y-bearing

depends not as much on its internal design as

on the way it is locked onto the shaft († fig. 2c)

as described in the chapter Axial load carrying

ability, page 34. In general, Y-bearing units with

housings made from grey cast iron or composite

material are more suitable for heavier or alter -

nat ing axial loads.

Y-bearing units with a pressed sheet steel

housing are only intended for light axial loads, in

particular the plummer block units incorporating

a rubber seating ring († fig. 2d).

c d

26