Page 9 - Dual-line-automatic

P. 9

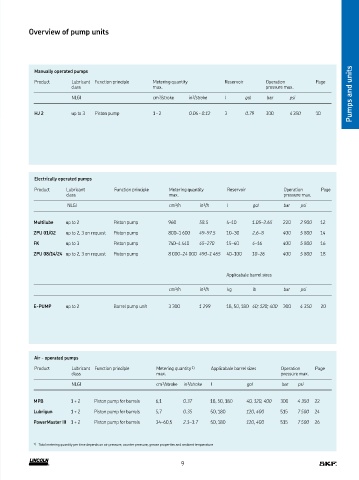

Overview of pump units

Pumps and units

Manually operated pumps

Product Lubricant Function principle Metering quantity Reservoir Operation Page

class max pressure max

NLGI cm 3 /stroke in 3 /stroke l gal bar psi

HJ 2 up to 3 Piston pump 1 - 2 0.06 - 0.12 3 0.79 300 4 350 10

Electrically operated pumps

Product Lubricant Function principle Metering quantity Reservoir Operation Page

class max pressure max

NLGI cm 3 /h in 3 /h l gal bar psi

Multilube up to 2 Piston pump 960 58.5 4–10 1.05–2.65 220 2 900 12

ZPU 01/02 up to 2, 3 on request Piston pump 800–1 600 49–97.5 10–30 2.6–8 400 5 800 14

FK up to 3 Piston pump 740–4 440 45–270 15–60 4–16 400 5 800 16

ZPU 08/14/24 up to 2, 3 on request Piston pump 8 000–24 000 490–1 465 40–100 10–26 400 5 800 18

Applicabale barrel sizes

cm 3 /h in 3 /h kg lb bar psi

E-PUMP up to 2 Barrel pump unit 3 300 1 299 18, 50, 180 40; 120; 400 300 4 350 20

Air - operated pumps

Product Lubricant Function principle Metering quantity 1) Applicabale barrel sizes Operation Page

class max pressure max

NLGI cm 3 /stroke in 3 /stroke l gal bar psi

MPB 1 + 2 Piston pump for barrels 6,1 0.37 18, 50, 180 40, 120, 400 300 4 350 22

Lubrigun 1 + 2 Piston pump for barrels 5,7 0.35 50, 180 120, 400 515 7 500 24

PowerMaster III 1 + 2 Piston pump for barrels 34–60,5 2.1–3.7 50, 180 120, 400 515 7 500 26

1) Total metering quantity per time depends on air pressure, counter pressure, grease properties and ambient temperature

9