Page 180 - Rollingbearings

P. 180

B.6 Bearing interfaces

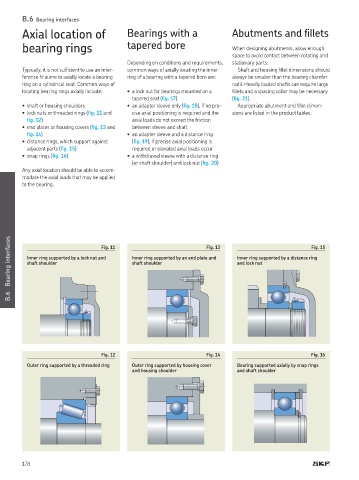

Axial location of Bearings with a Abutments and illets

bearing rings tapered bore When designing abutments, allow enough

space to avoid contact between rotating and

Depending on conditions and requirements, stationary parts

Typically, it is not suficient to use an inter- common ways of axially locating the inner Shaft and housing illet dimensions should

ference it alone to axially locate a bearing ring of a bearing with a tapered bore are: always be smaller than the bearing chamfer

ring on a cylindrical seat Common ways of radii Heavily loaded shafts can require large

locating bearing rings axially include: • a lock nut for bearings mounted on a illets and a spacing collar may be necessary

tapered seat (ig. 17) (ig. 21)

• shaft or housing shoulders • an adapter sleeve only (ig. 18), if no pre- Appropriate abutment and illet dimen-

• lock nuts or threaded rings (ig. 11 and cise axial positioning is required and the sions are listed in the product tables

ig. 12) axial loads do not exceed the friction

• end plates or housing covers (ig. 13 and between sleeve and shaft

ig. 14) • an adapter sleeve and a distance ring

• distance rings, which support against (ig. 19), if precise axial positioning is

adjacent parts (ig. 15) required or elevated axial loads occur

• snap rings (ig. 16) • a withdrawal sleeve with a distance ring

(or shaft shoulder) and lock nut (ig. 20)

Any axial location should be able to accom-

modate the axial loads that may be applied

to the bearing

Bearing interfaces Inner ring supported by a lock nut and Inner ring supported by an end plate and Inner ring supported by a distance ring

Fig. 13

Fig. 15

Fig. 11

shaft shoulder

shaft shoulder

and lock nut

B.6

Fig. 12 Fig. 14 Fig. 16

Outer ring supported by a threaded ring Outer ring supported by housing cover Bearing supported axially by snap rings

and housing shoulder and shaft shoulder

178